From design to the bags delivered in your warehouse,

we can take care of all steps including design, sampling, manufacturing,

quality assurance and shipment.

Whether your Quantities are Large or Small, your products Technical or Fashionable,

They are in Good Hands.

Our Core Strength is R&D

See how and why

Rely on our expertise and yield your profit thanks to proficient product development

We handle orders from

300 pces per Style

With a proven record of goods on time complying with the highest quality requirements we will carry on your project with confidence

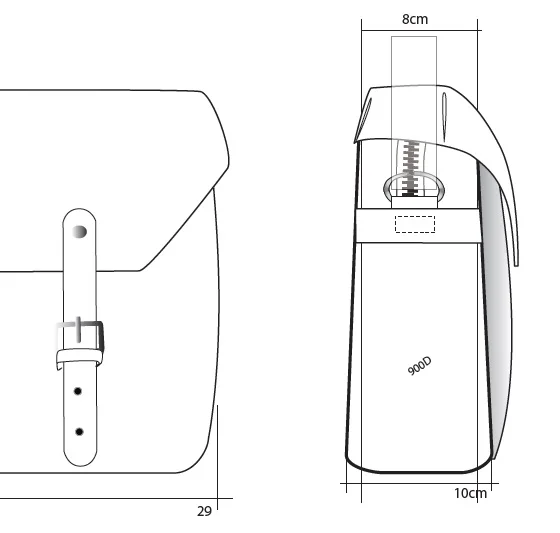

We specialize in Fabric Bags

(nylon, RPET, canvas, etc..)

Explore here a selection of the products we developed and manufactured.