Eco-friendly textiles are not only the ones made out of natural fibers.

Amongst the various eco-friendly options offered nowadays,

recycled polyester appears to us

to be the most relevant and durable one.

Recycling is a priority that cannot be pushed away any longer

Amongst the waste generated by the food industry, there are tons of plastic water and soda bottles.

Promoting recycling of this plastic waste has become a critical means of fighting against plastic pollution of the oceans or excessive emission of carbon dioxide.

Woven RPET fibers give plastic bottles a new life by being used in clothing, bags, furniture or decoration.

In addition, RPET fiber is also 100% recyclable !

1 M2 of 600D 100% RPET requires 17 plastic bottles

These are 17 bottles less at sea

waiting for an improbable and very slow natural degradation.

A well-honed production process that results in very qualitative fibers

1- Plastic bottles are collected in sorting centers, where they are washed. Opaque and transparent plastic bottles are sorted and then baled before being crushed into thin flakes.

These pellets are the basic material for PET recycling. The PET, Polyethylene terephthalate, is from the POLYESTER family, and can be molded again into bottles (or other products such as pens) or fibers.

2- The flakes are in turn transformed into granules through a hot air process, they are then dried and projected into high temperature tubes to form a thick liquid .

This paste then passes into a dye filter and ends in a strainer creating filaments.

These filaments solidify through their contact with air, they are then drawn on hot metal rollers to realign polyester molecules perfectly. The resulting yarn is then wound on reels and ready to be woven.

This yarn is composed of long and regular RPET fibers

that allow the resulting fabric to have

the same physical properties as virgin polyester.

A true environmental contribution without compromising performance : No “GREENWASHING”

1- Like their counterparts made from hydrocarbons, recycled PET fabrics offer high resistance to abrasion, durability and a fair waterproofness.

However, only RPET fabrics contribute to limiting carbon gas emissions and spare fossil fuels.

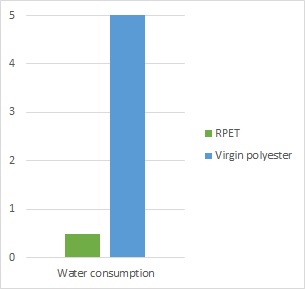

2- See below some "green" indicators :

See also : Textile Exchange 2025 Rpet challenge for more insights

RPET production produces 65.5% less carbon than virgin polyester and 12% less than cotton

RPET production needs 1/10th of water compared to virgin polyester

RPET’s production needs only 30% of the energy required for virgin polyester’s production

Preferring RPET to virgin fabrics saves fossil resources

Integrity of recycling processes : what guarantees?

Knowing that :

recycling is an expensive process

processing companies do not all have a good moral integrity

It is impossible to detect with the naked eye any difference between a RPET fabric and a virgin polyester fabric

it is legitimate to wonder :

“Is my RPET fabric resulting from post-consumer recycling “

Several labels formalize the probity of recycling processes and the compliance of production processes to international ethical standards.

Among them, the oldest, the GRS (Global Recycled Standard) , is an inspection body administered by the international organization TEXTILE EXCHANGE which establishes:

Traceability in the recycling process,

The exact origin of the components of the recycled textile fiber,

The absence of prohibited chemical substances,

Compliance of the water treatment,

Ethical and social compliance of processing and weaving companies

The designer's point of view : seduced by the qualities and ease of use of the RPET

RPET fabrics behave like regular polyester ones, they are strong and durable with a regular texture. They allow to create a wide variety of finished products, while being themselves 100% recyclable.

RPET has a good resistance to UV and wear as well as to elongation - not to mention its great quality: lightness.

RPET fiber can replace virgin (conventional) polyester in all current polyester fabrics.

It is therefore easy to offer

a sustainable finished product

without changing its design or construction.

You also want to become a player in the green industry ...

You have more information about RPET and you want to share it...

You are a professional in product design or manufacturing and you want to see samples of rPET materials ....

Plan ahead ! Download the China Holidays calendar for 2023